Group Profile

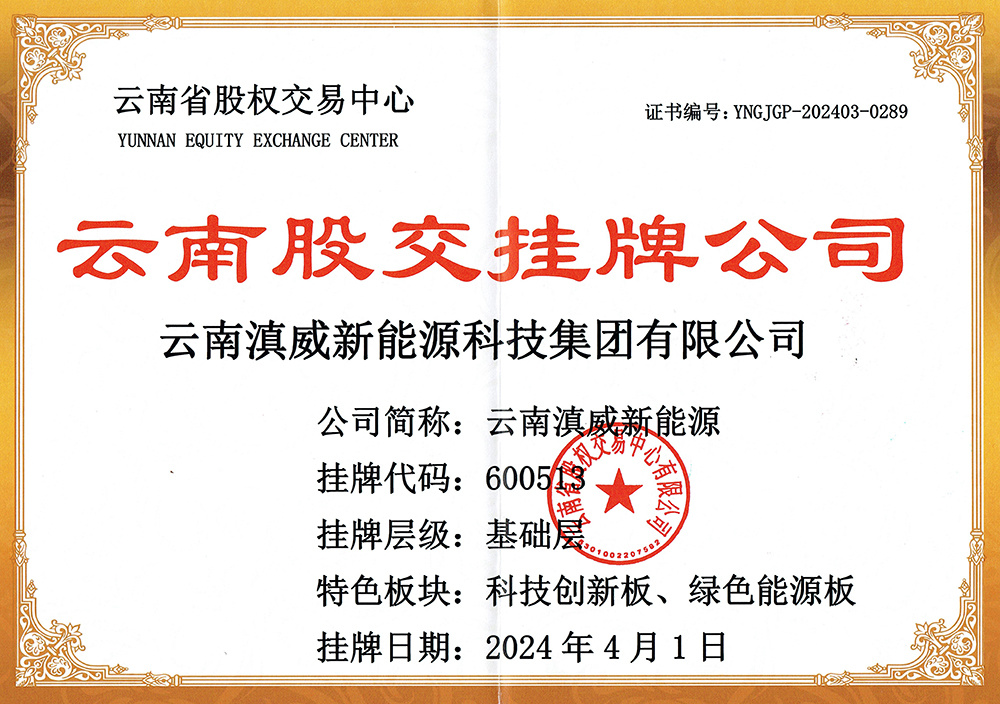

Yunnan Dian Wei New Energy Technology Group Co., Ltd. was established in 2008. The company is located in Haikou Industrial Park, Kunming City, which is like spring all the year round. The company has paid in a registered capital of 50 million yuan. It has more than 40000 square meters of modern production workshop. It has an annual output of 10000 units/sets of new energy vehicle charging pile production line; it has an annual output of 50000 units/sets of solar photovoltaic equipment controller and inverter production line; it has a metal equipment production line with 50000 sets of street lamps and monitoring rods; it has an annual output of 50000 units/sets of solar water heater production line; The automation degree of each production line, the stability of product quality and the ratio of each component have reached the advanced level of the same industry in China.

The group was founded in

Paid-in registered capital

Modern production workshop

More than 40000 square meters of modern production workshop

Annual output of 10000 units/sets of new energy vehicle charging pile production line

Annual output of 50000 units/sets of solar photovoltaic equipment controller and inverter production line

50000 sets of metal equipment production line for street lamps and monitoring rods

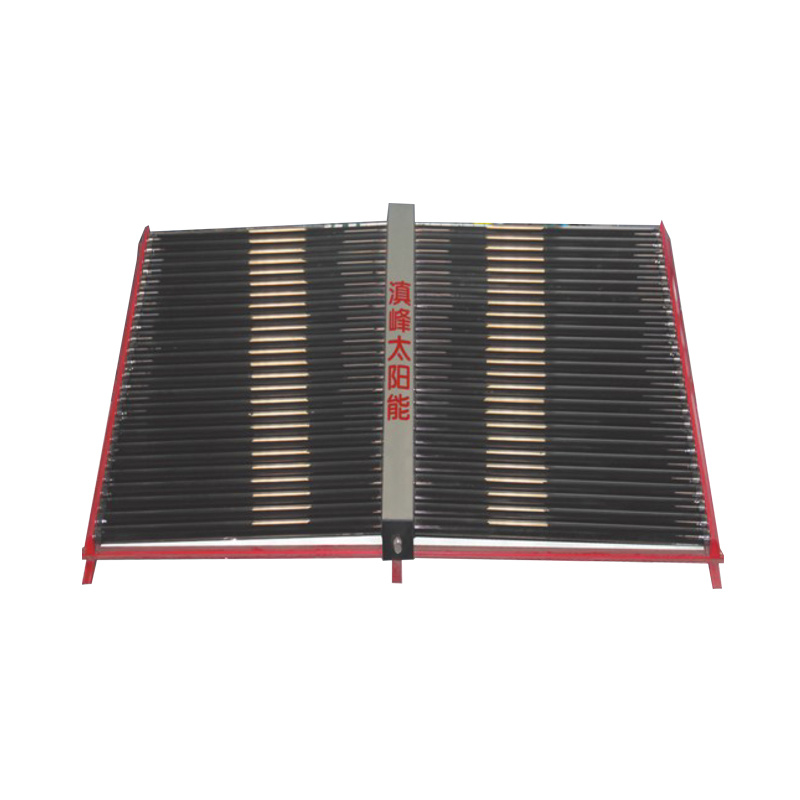

Annual output of 50000/set of solar water heater production line

Dian Wei Group ·

Committed to a green and sustainable future

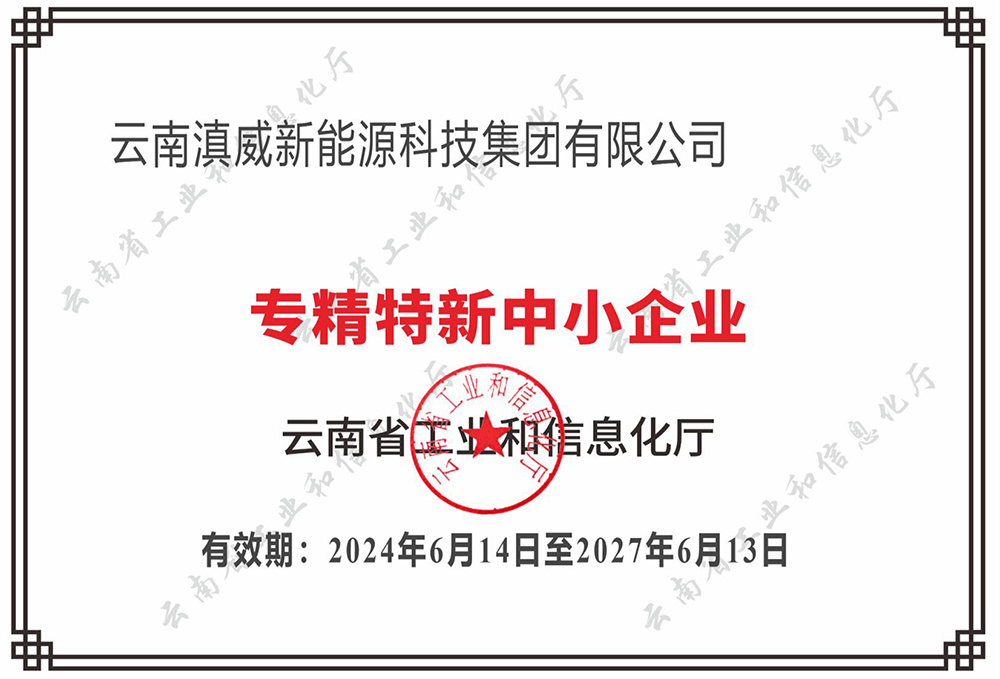

The company has been working unremittingly in the field of new energy for nearly 20 years. The company has established long-term cooperative relations with Yunnan Normal University and Chuxiong Normal University in scientific research and personnel training, continuously improving our independent innovation ability; realizing the horizontal expansion and vertical extension of the industrial chain; complete industrial chain, excellent technical team, professional sales and after-sales team to cooperate, dian Wei Group has been unanimously recognized by industry experts, enterprises and customers; at present, it has grown into a provider of new energy products and solutions with a complete industrial chain of new energy industry in Yunnan Province.

Product Service

Application Case

7KW slow charging in the basement of Hushan Dajing Community, Guiyang City, Guizhou Province.

CHOOSE DIAN WEI ·

CHOOSE REST ASSURED

The company has been working unremittingly in the field of new energy for nearly 20 years, constantly improving our independent innovation ability, realizing the horizontal expansion and vertical extension of the industrial chain, and has grown into a provider of new energy products and solutions with a complete industrial chain of new energy industry in Yunnan Province.

Dian Wei Group ·

Enterprise advantage

Blog

2024/12/20

Requirements for Installing Electric Vehicle Charging Stations

The installation of electric vehicle charging stations needs to meet a series of conditions and comply with relevant regulations, which mainly include parking space conditions, power supply conditions, safety conditions, compliance conditions, and other conditions.

→The installation of electric vehicle charging stations needs to meet a series of conditions and comply with relevant regulations, which mainly include parking space conditions, power supply conditions, safety conditions, compliance conditions, and other conditions.

The input end of the charging pile is directly connected to the AC power grid, and the output end is equipped with charging plugs for charging electric vehicles. Charging piles generally provide two charging methods: regular charging and fast charging. Users can swipe a specific charging card on the human-machine interaction interface provided by the charging pile to perform corresponding charging operations and print cost data. The display screen of the charging pile can show data such as charging amount, cost, and charging time.

Safety Inspection: Before cleaning the components, check the monitoring records for any abnormal power output entries, analyze whether it may be caused by leakage, and inspect the connection wires and related components for any damage or adhesion. Additionally, use a voltage tester to test the aluminum frame, brackets, and tempered glass surface of the components to eliminate the risk of electric leakage and ensure personal safety.

The installation of electric vehicle charging stations needs to meet a series of conditions and comply with relevant regulations, which mainly include parking space conditions, power supply conditions, safety conditions, compliance conditions, and other conditions.

The input end of the charging pile is directly connected to the AC power grid, and the output end is equipped with charging plugs for charging electric vehicles. Charging piles generally provide two charging methods: regular charging and fast charging. Users can swipe a specific charging card on the human-machine interaction interface provided by the charging pile to perform corresponding charging operations and print cost data. The display screen of the charging pile can show data such as charging amount, cost, and charging time.

Safety Inspection: Before cleaning the components, check the monitoring records for any abnormal power output entries, analyze whether it may be caused by leakage, and inspect the connection wires and related components for any damage or adhesion. Additionally, use a voltage tester to test the aluminum frame, brackets, and tempered glass surface of the components to eliminate the risk of electric leakage and ensure personal safety.