-

-

-

-

-

Attract Investment

-

-

-

Contact Us

Thermal bucket

The non-welding process uses the latest biting technology, physically folding stainless steel materials and biting them together, adding silicone to prevent leakage at the biting points; the inlet and outlet, exhaust port, and air energy interface all use the biting process, achieving a fully non-welded design. The production of the insulation barrel mainly relies on CNC machinery to control product quality, with low dependence on employee skill levels, and the scrap rate is below 1‰, effectively controlling production costs.

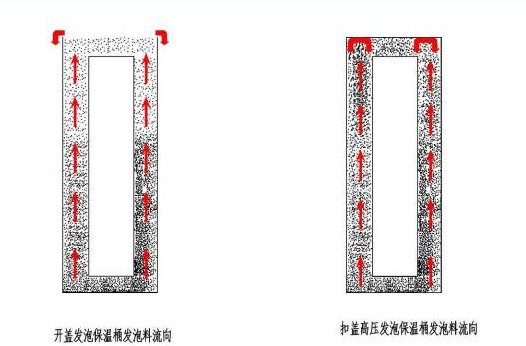

The production of the insulation barrel adopts the latest production technology, based on the traditional vertical open-cover foaming process, through innovative modifications to the equipment, achieving high-pressure cover foaming for the insulation barrel, allowing the foaming amount to expand autonomously in a sealed space, appropriately increasing the equivalent, causing the foaming amount to continue to flow back down under the dual action of the upper cover and gravity during the expansion process. This forms an integral insulation layer at both ends and the barrel body. Under the same foaming amount formula, the conventional open-cover foaming process has a minimum density of 35-36KG/M3 at the lowest end of the insulation layer and a density of 30-31KG/M3 at the top end, resulting in a significant density difference; the high-pressure cover foaming solar insulation barrel has basically the same density at both ends and the barrel body, with a density of 33KG/M3.

During the production process, different specifications of insulation barrels require changing molds in different batches, leading to low production efficiency, high labor input, and high indirect costs. By modifying the equipment, a pressure regulator is added to the upper cover to reduce the direct impact of high-pressure foaming on the end cover; a positioning ring is added to the bottom, which reduces the time for changing molds and reinforces the insulation barrel, preventing shaking and ensuring uniformity of the insulation layer.

High-pressure cover foaming production line diagram for insulation barrels.

As shown in the figure above: in the traditional open-cover foaming process, the upper end cover is placed on the barrel body after the insulation layer has been foamed, resulting in insufficient density of the insulation layer due to a small amount of insulation material, while too much insulation material causes overflow, leading to waste of raw materials and difficulty in cleaning; the latter figure shows the exclusive cover foaming process adopted by our company, where after the end covers are modified, the foaming amount enters through the feeding port of the upper end cover, appropriately increasing the equivalent so that the insulation material flows down under the dual action of the upper end cover blocking and gravity, resulting in a higher degree of integration of the entire insulation layer and better insulation effect.

Previous

Related Products

The pedestal charging pile is a convenient and efficient charging device, widely used in the charging scenarios of electric vehicles. Its unique design features a pedestal structure, which occupies a small footprint and is easy to install. The length of the charging pile is moderate, adhering to ergonomic design principles, making it simple to operate. Additionally, this charging pile is equipped with various safety protection measures to ensure a safe and reliable charging process. The maximum output power and charging speed vary depending on the specific model, capable of meeting the charging needs of different electric vehicles. Furthermore, the pedestal charging pile also features an intelligent control system that can monitor the charging status in real-time, providing electric vehicle users with a convenient charging experience. In summary, the pedestal charging pile is an efficient, safe, and intelligent charging device that provides strong support for the popularization and promotion of electric vehicles.

Photovoltaic power generation system controller and inverter

Photovoltaic power generation system controller and inverter

Contact Information

Address: First Floor, Administrative Committee of Haikou Industrial Park, Xishan District, Kunming City, Yunnan Province

Store: Building B1-2, Hongju Lamps and Curtain Wholesale Market, Guandu District, Kunming City

Copyright©Yunnan Dian Wei New Energy Technology Group Co., Ltd. Power by 300.cn

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.