Solar Thermal System Solutions

1. Household and engineering type single machine water heaters, support OEM and processing with supplied materials.

Insulated water tank:The inner tank of the insulated water tank is made of SUS304-2B food-grade stainless steel, safe and hygienic; the outer tank material is made of color steel plate with high-temperature baking paint; the insulation material is high-quality polyurethane, with a thickness of 50mm, and insulation time not less than 72 hours.

Vacuum tube:Using 58×1800 purple gold three-high tubes, made of double-layer high borosilicate 3.3 special hard glass; the vacuum layer inside the tube is 5*10-3Pa; solar radiation absorption rate ≥93%; thermal emissivity ≤6%; can withstand impacts from hail with a diameter of less than 25mm.

Bracket:Made of galvanized steel, mechanically formed. Advanced fully automatic CNC bracket equipment in Yunnan, with small error and high efficiency.

2. Engineering type hot water system

Water heater bracket:

1) The centralized heating type bracket is made of galvanized sheet, fully CNC formed in one go, with electrostatic spraying for anti-corrosion treatment, and installed with foot pads to better protect the original roof. No on-site welding or painting is required, and standardized screws are used for installation, which is environmentally friendly and safe.

2) Collector bracket orientation: The orientation is due south or 0-15° west of due south, ensuring that the collector receives sufficient sunlight throughout the year.

Solar insulated water tank

The inner tank of the insulated water tank is made of SUS-304/2B food-grade (for medical and food containers) stainless steel plate; inner tank: (the inner tank material is made of 304/2B stainless steel)

① To improve the overall strength of the inner tank, the barrel body is rolled with ribs;

② To improve reliability, each outlet of the barrel body uses a detachable hard connection joint (with thread), which is convenient for maintenance;

③ Passed airtightness testing to prevent and eliminate potential hazards, no hot water leakage;

④ Passed pressure testing to bear the natural pressure of water;

⑤ For easy drainage, a drainage pipe is set at the bottom;

⑥ The inner tank of the water tank uses computer-controlled automatic high-frequency welding technology, which has characteristics that other welding methods cannot achieve;

2) Insulation layer: Made of high-density polyurethane. The process is one-time overall foaming.

3) Protective layer (outer tank): Made of stainless steel plate, double-sided protective film, with good comprehensive performance;

4) Insulation process of the water tank:

The insulation material uses polyurethane overall high-pressure foaming insulation, using a high-pressure polyurethane overall foaming machine, the foaming process is the latest technology, using ultra-high pressure foaming, with temperature and flow fully controlled by computer, ensuring that the black and white materials collide and merge more fully and evenly, thus the foaming quality and stability of polyurethane reach world-class quality standards, with high density, high closed-cell rate, good high-temperature resistance, and not easy to shrink. The insulation layer thickness is greater than 60mm, with an average heat loss coefficient U1=1.8W/(㎡·℃), national standard not exceeding 5.0W/(㎡·℃). At an ambient temperature of 10℃, the water temperature of 55℃ does not drop more than 5℃ in 24 hours.

| Specifications and models | QB-WF-LJ-50/58-D |

| Inner box specifications (mm) | 2000×90×80 |

| Inner box material thickness (mm) | δ0.31/0.41 |

| Inner box material | SUS304 stainless steel |

| Outer box specifications (mm) | 2100×180×160 |

| Material thickness (mm) | 0.31 |

| Outer box material | Brushed color steel plate |

| Insulation layer thickness (mm) | 50 |

| Insulation material | Polyurethane |

| Test pressure (Mpa) | 0.1 |

| Working pressure (Mpa) | 0.05 |

| Inlet diameter | DN32/40 |

| Outlet diameter | DN32/40 |

| Vacuum tube interface (mm) | Φ58 |

| Number of vacuum tubes configured | 50 (pieces) |

| Daily production of hot water above 45℃ under normal sunlight (L) | 500 |

| Net weight (Kg) | 11.5±0.5 |

| Collector volume (L) / vacuum tube volume (L) | 24/150 |

| Gross weight (Kg) | 12.5±0.5 |

| Total area (㎡) | 8.16 |

| Packaging dimensions (mm) | 2100×250×250 |

3. Industrial solar dryer steam system

Note: Products are continuously innovated, and performance is continuously improved. The above technical parameters are for reference only.

Insulated water tank

Vacuum tube

Water heater bracket

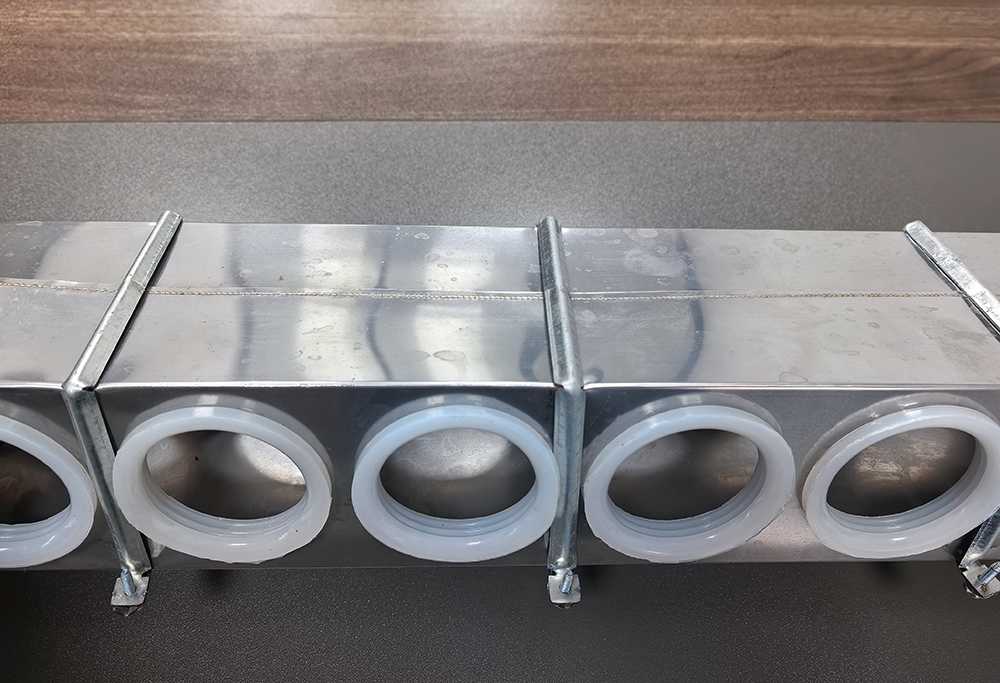

Engineering Joint Box: Patent Technology, Compression Resistant Clamp

Industrial Solar Dryer Steam System

Related Products

The pedestal charging pile is a convenient and efficient charging device, widely used in the charging scenarios of electric vehicles. Its unique design features a pedestal structure, which occupies a small footprint and is easy to install. The length of the charging pile is moderate, adhering to ergonomic design principles, making it simple to operate. Additionally, this charging pile is equipped with various safety protection measures to ensure a safe and reliable charging process. The maximum output power and charging speed vary depending on the specific model, capable of meeting the charging needs of different electric vehicles. Furthermore, the pedestal charging pile also features an intelligent control system that can monitor the charging status in real-time, providing electric vehicle users with a convenient charging experience. In summary, the pedestal charging pile is an efficient, safe, and intelligent charging device that provides strong support for the popularization and promotion of electric vehicles.

Photovoltaic power generation system controller and inverter

Photovoltaic power generation system controller and inverter