-

-

-

-

-

Attract Investment

-

-

-

Contact Us

Charging and swapping solutions

1. Preliminary investigation and planning before site establishment

Assist clients in understanding the relevant policies and management regulations of the site area, establish a communication mechanism among relevant personnel and units; design and plan the project construction scheme based on sufficient communication, determine the specific responsibilities of each link such as electricity, site, construction, acceptance, and operation, and provide a closed-loop execution plan to help clients build sites with confidence, efficiency, cost savings, and safety.

2. Optimal charging pile matching scheme, charging pile equipment selection

Different vehicle models and usage environments require detailed refinement for the selection of charging piles, ensuring that they meet usage needs while achieving high cost-effectiveness, low operating costs, short recovery periods, and low power loss.

Our company is a research and production enterprise for charging piles, familiar with the charging needs of various vehicle models, and can provide customized or specialized charging pile equipment for users.

Battery swapping station scheme

Battery swapping stations are an alternative energy supply solution designed to improve charging efficiency, offering advantages of time savings and increased efficiency. Currently, they are mainly used for energy supply in operating vehicles, widely used in small vehicles such as taxis and ride-hailing cars; large vehicles like tractors, dump trucks, and concrete mixers are suitable for short-distance transportation scenarios in logistics parks, freight stations, mixing stations, mines, ports, and steel mills. A single vehicle swap takes only 2-5 minutes, and the charging and swapping scheme ensures a charging efficiency of over 95%, operating normally at temperatures between -30° and +50°.

3. Technical guidance for site establishment

4. Installation and debugging services

5. Pre-sales and after-sales services, technical and personnel support

6. Free training for technical personnel

Note: Products are continuously innovated, and performance is continuously improved; the above technical parameters are for reference only.

Slow charging piles: wall-mounted type, column type

Slow charging piles: wall-mounted type, column type

Fast charging pile: wall-mounted, floor-standing

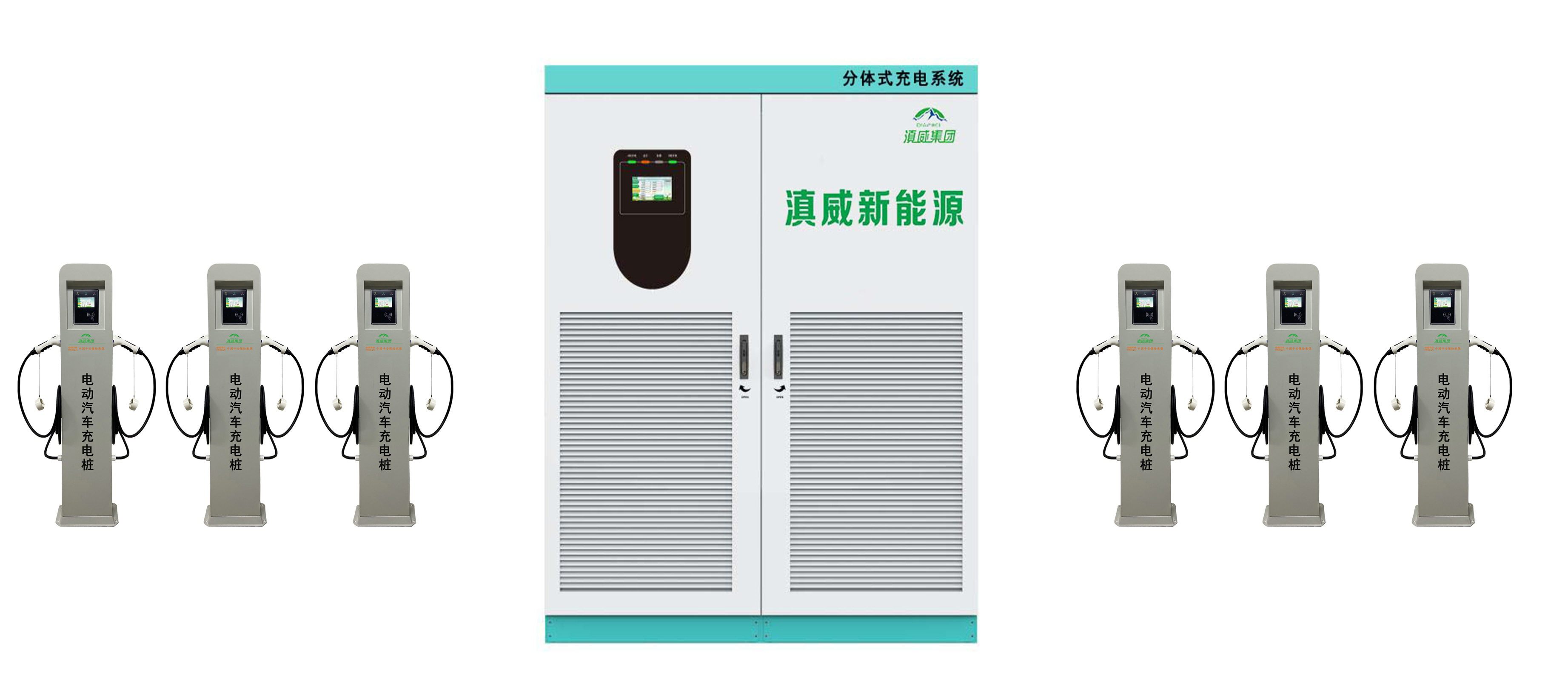

Charging pile: split type, 4-12 guns

Charging pile: split type, 4-12 guns

Charging pile: split type, 4-12 guns

Related Products

The pedestal charging pile is a convenient and efficient charging device, widely used in the charging scenarios of electric vehicles. Its unique design features a pedestal structure, which occupies a small footprint and is easy to install. The length of the charging pile is moderate, adhering to ergonomic design principles, making it simple to operate. Additionally, this charging pile is equipped with various safety protection measures to ensure a safe and reliable charging process. The maximum output power and charging speed vary depending on the specific model, capable of meeting the charging needs of different electric vehicles. Furthermore, the pedestal charging pile also features an intelligent control system that can monitor the charging status in real-time, providing electric vehicle users with a convenient charging experience. In summary, the pedestal charging pile is an efficient, safe, and intelligent charging device that provides strong support for the popularization and promotion of electric vehicles.

Photovoltaic power generation system controller and inverter

Photovoltaic power generation system controller and inverter

Contact Information

Address: First Floor, Administrative Committee of Haikou Industrial Park, Xishan District, Kunming City, Yunnan Province

Store: Building B1-2, Hongju Lamps and Curtain Wholesale Market, Guandu District, Kunming City

Copyright©Yunnan Dian Wei New Energy Technology Group Co., Ltd. Power by 300.cn

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.